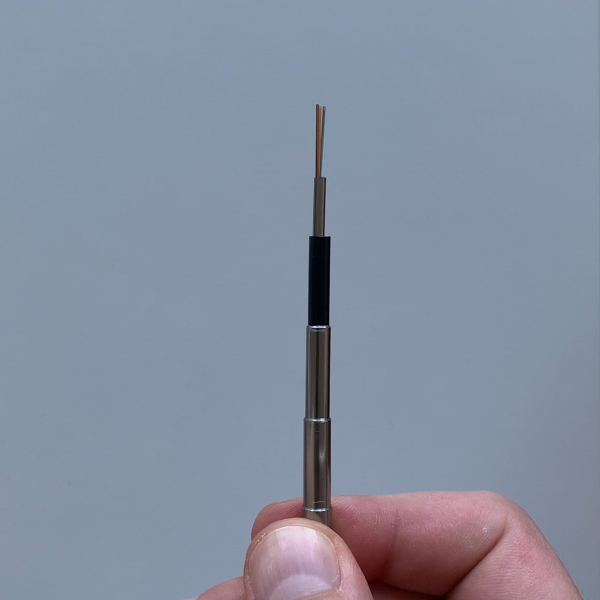

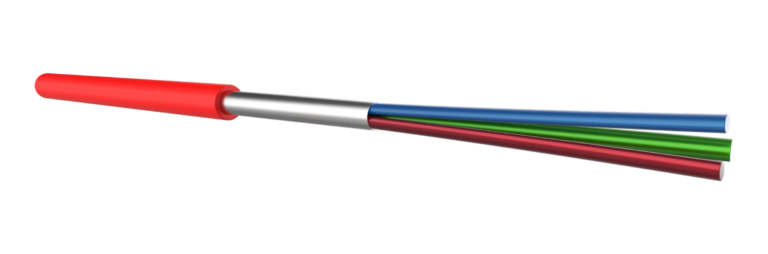

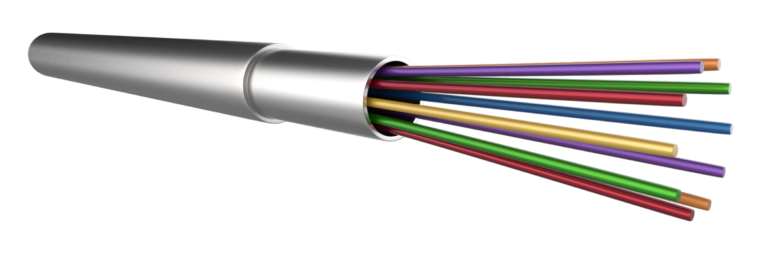

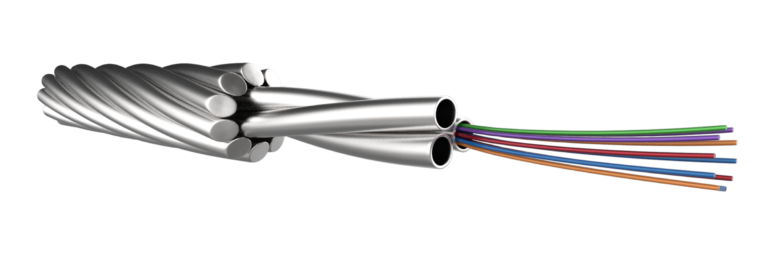

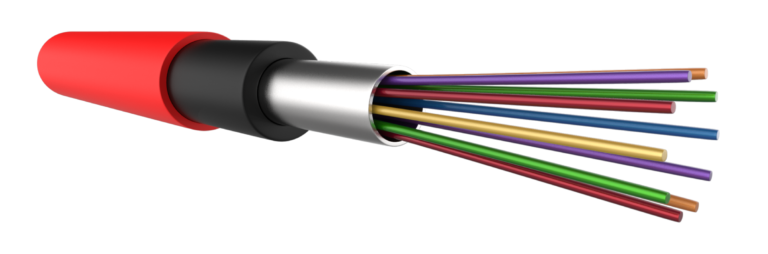

For application, where a stainless-steel tube is needed to protect optical fibers against the surrounding influence, one abbreviation is catching one of the most important attention to consider. The so called “EFL”.

“EFL” stands for Excess Fiber Length and means the overlength of the optical fibers against the metal tube.

Every material is having a thermal coefficient, one is more, the other less or close to zero. Same in a fiber in metal tube. If the metal cable is exposed for example to a continuous temperature of 150°C (302°F), the metal is expanding approximately 16 x 10-06/K. The fiber in contrast expands almost nothing. Considering, that the fiber length inside the tube is exactly the length of the metal tube, the tension would get in an area, where the fiber would be useless because of the extreme stress which can cause even a break of the fiber. To countervail this effect, more length of a fiber is placed inside the metallic tube which can be exactly calculated and managed during manufacturing to compensate the thermal expansion of the tube. As we know the behavior of the steel and the expected temperature of the application, it is possible to prepare this “EFL” value for it in order to ensure a safe and fully working operation in the field. But there´s a limitation of putting more fibers inside the tube which depends on fiber type and tube dimension. Once the critical bending value of a fiber is reached, the transmitted light can leave the fiber which results in optical attenuation and this needs to be avoided.

To manufacture a FIMT which contains exactly the needed EFL for the application, NBG is one of the leading companies worldwide to reach the exact values during production.