ARMOURED OPTICAL FIBER

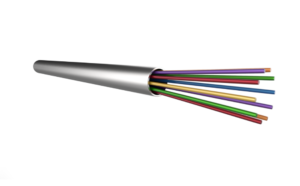

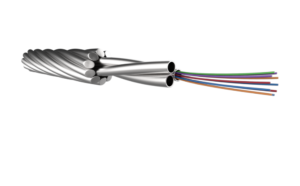

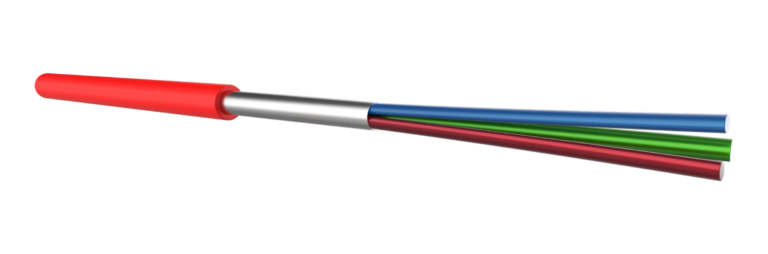

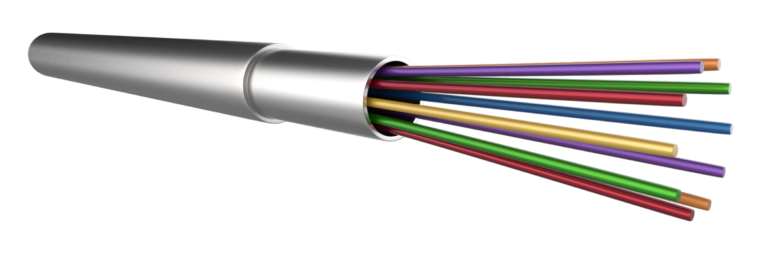

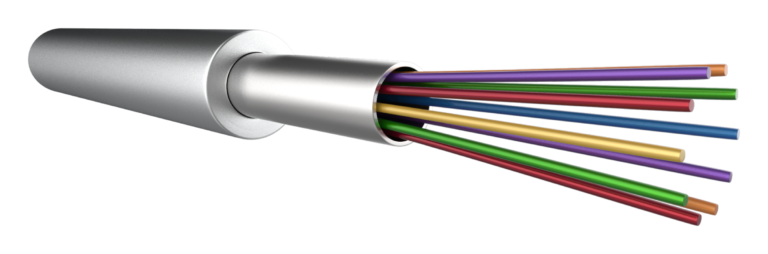

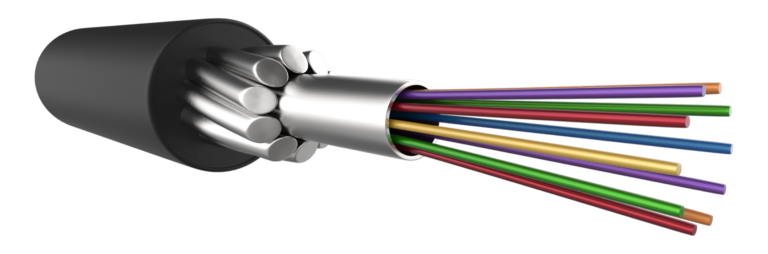

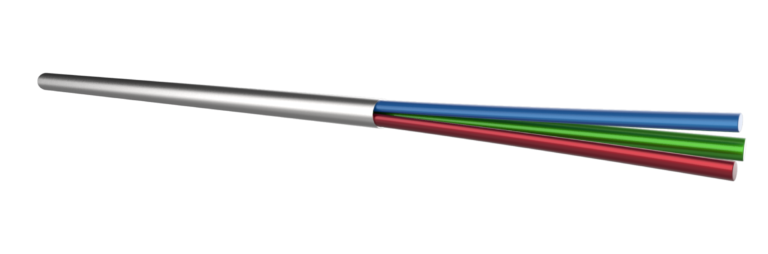

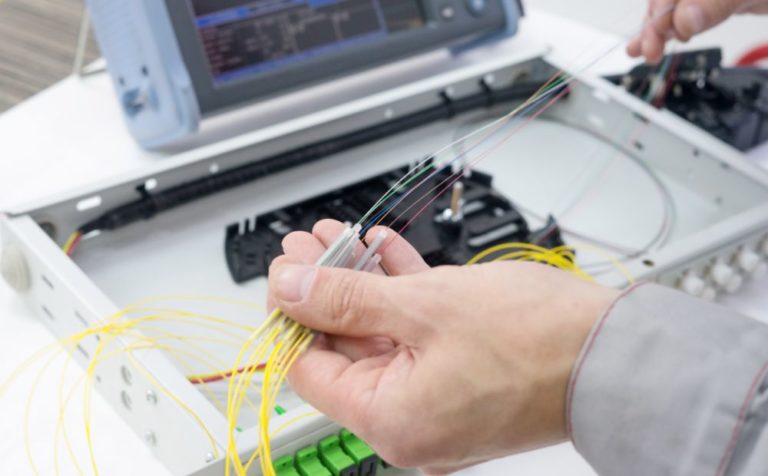

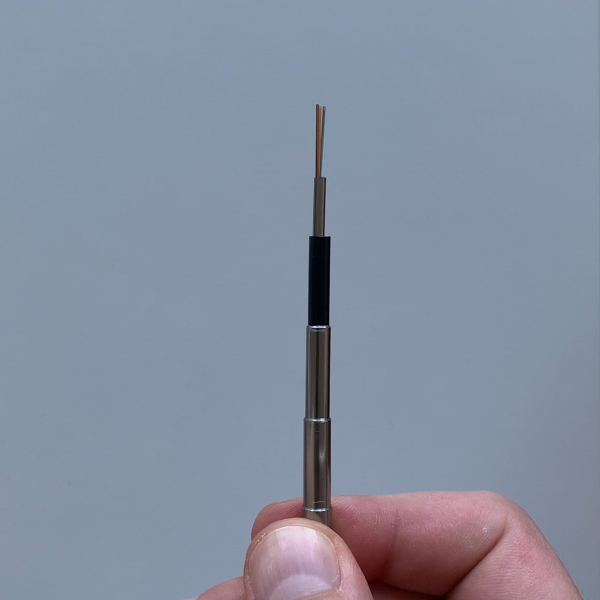

Fiber in metal tube (FIMT)

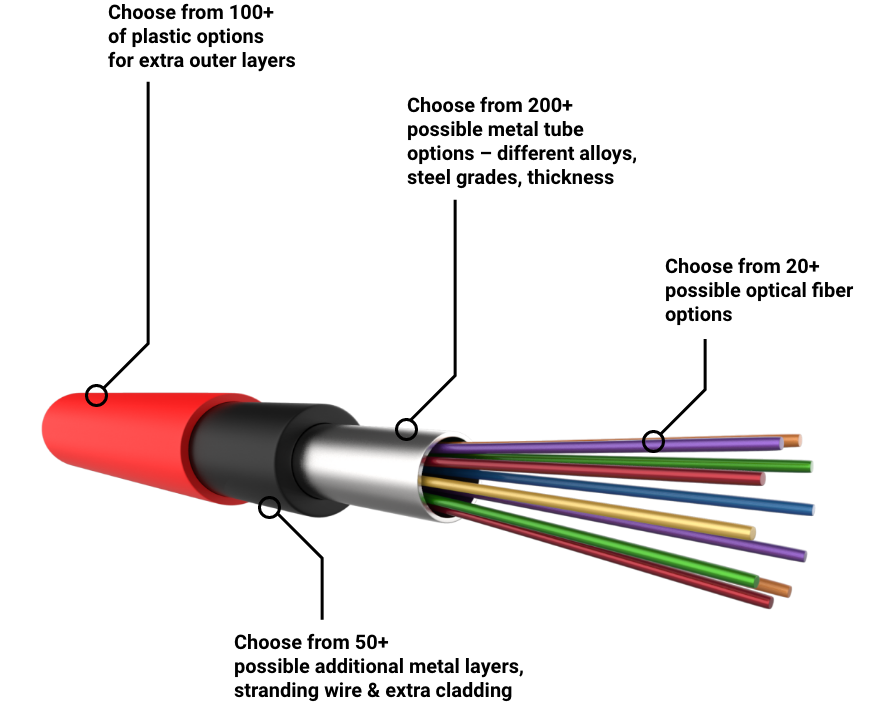

- Over 80,000 possible configurations

- Products designed precisely to your needs

- Rapid design, prototyping & production

+ 80.000 possible configurations, each suitable for multiple applications.

Layers

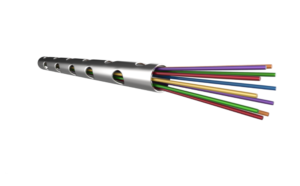

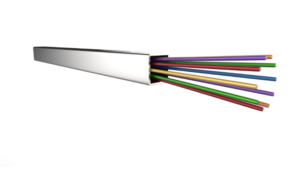

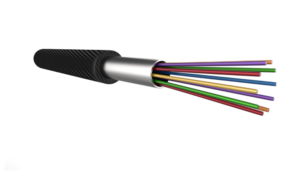

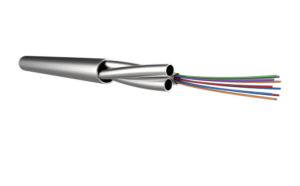

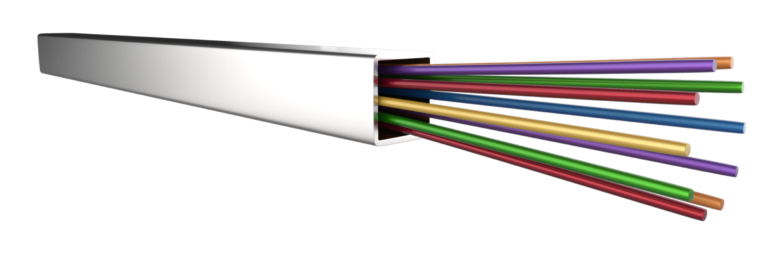

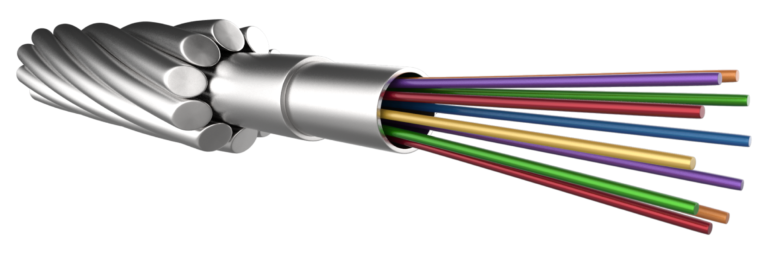

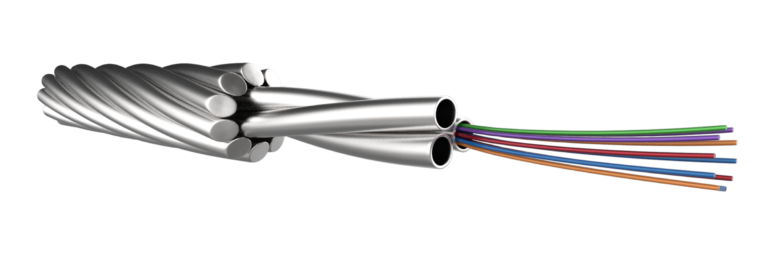

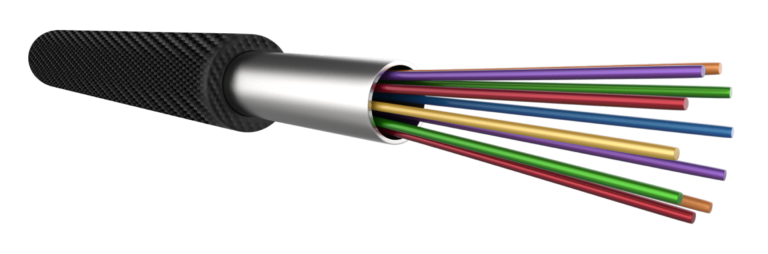

Stainless Steel Tubes can be combined with additional layers, which do not necessarily need to be a metal tube too.

Stainless Steel Tubes can be combined with additional layers.

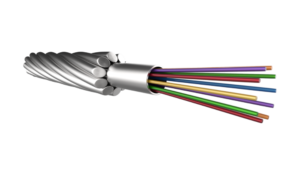

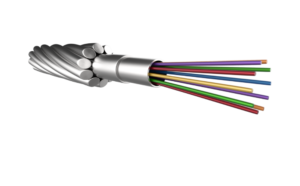

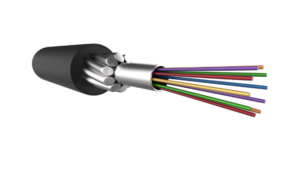

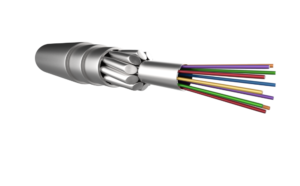

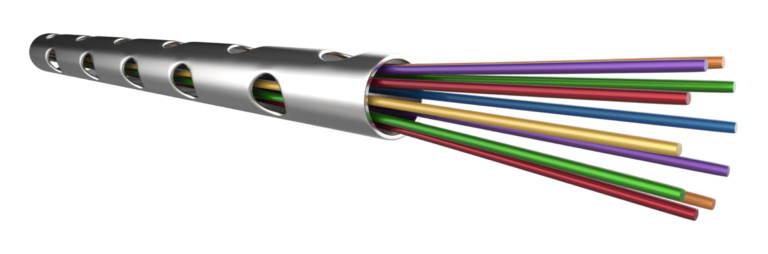

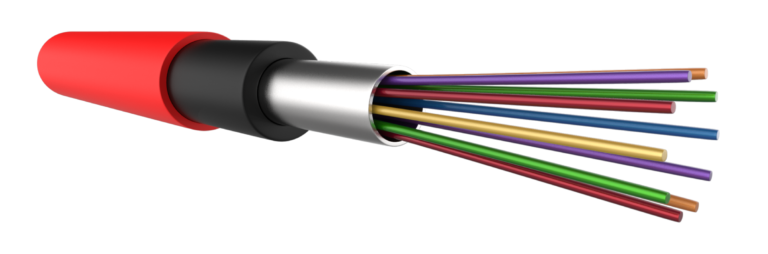

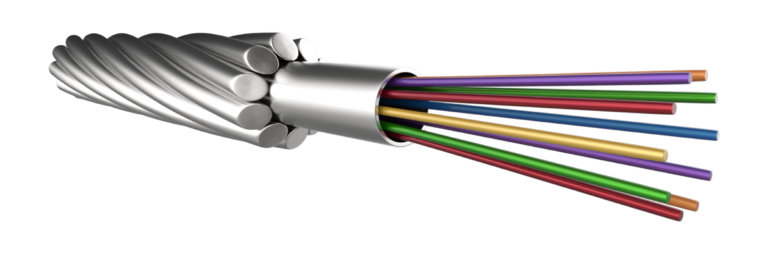

Additional metal layers

![]()

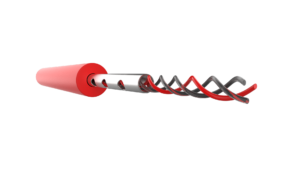

Stranding wire

![]()

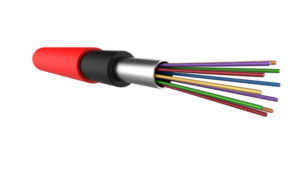

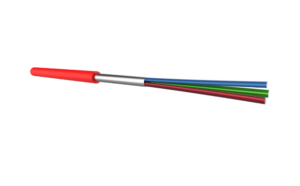

Polymer

![]()

Aluminum

![]()

Common Stainless Steel Grades: | |

ASTM/AISI/ANSI | EN # |

304 | 1.4301 |

304L | 1.4306 |

316L | 1.4404 |

316Ti | 1.4571 |

Common Nickel Alloy Grades: | |

ASTM/AISI/ANSI | EN # |

Alloy 825 | 2.4858 |

Alloy 625 | 2.4856 |

Invar 36 | 1.3912 |

Filling compound

In general, filling compounds for Fiber in Metal Tubes are used to protect the fibers from moisture and mechanical stress.

- Wide temperature range:

– 60° up to + 200 °C - High, medium or without hydrogen scavenging properties

- Short-term exposure up to + 300 °C

- Full synthetic thixotropic compound

- Non-toxic

Optical fiber

Diameter, coating, bend resistance & coloring are all things that must be considered when choosing fiber a type.

We split fiber into two main categories:

Common Standard Fiber Types:

- G.652.D

- G.657.A1

- G.657.A2

- G.655

- etc.

Common Speciality Fiber Types:

- Copper Coated Fibers

- Aluminum Coated Fibers

- Gold Coated Fibers

- Buffered Fibers

- Polyimide Coated Fibers

- etc.

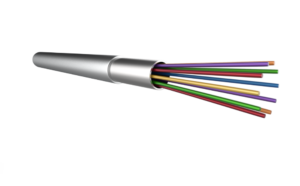

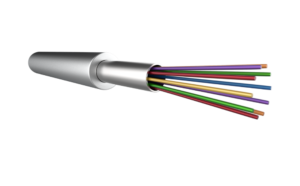

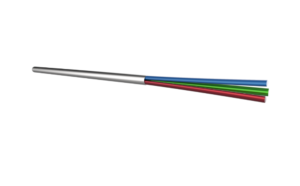

Single Layer Optical Core

Special Sensing Core

Quality? We embody it.

All our FIMT products are delivered with a test report

The reports are in accordance to EN 10204 /2.2 and include the following tests:

- Actual tube length measurement

- Actual tube diameter measurement

- Welding depth measurement

- Accurate EFL measurement

- Optical Fiber attenuation measurement

- Water penetration test, if applicable

How's FIMT made?

Peter Basic, our former head of R&D runs you through the FIMT production process.

Our latest FIMT insights

Why excess fiber length (EFL) matters?

For application, where a stainless-steel tube is needed to protect optical fibers against the surrounding influence, one abbreviation is catching

FIMT, FIST, SST? Deciphering the abbreviations.

When you work or deal with cables which contain optical fiber, you probably noticed designations like “FIMT”, “FIST”, “SST” or

Richard Groffie

Vice President of Sales “Challenge me with your project”