FIBER OPTIC SENSING

TUNNEL MONITORING

Every Millimeter Counts.

We at NBG love details and information, even over far distances. With our technology you are able to measure in real time your tunnel structure. Cracks can be sooner discovered or monitored. Learn more about this system on this page.

What can be monitored?

- Displacement

- Integrity

- Crack

- Convergence

- Strain

Technology

SHM

Structural Health Monitoring

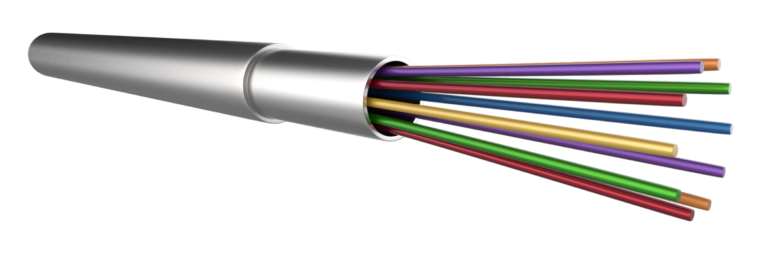

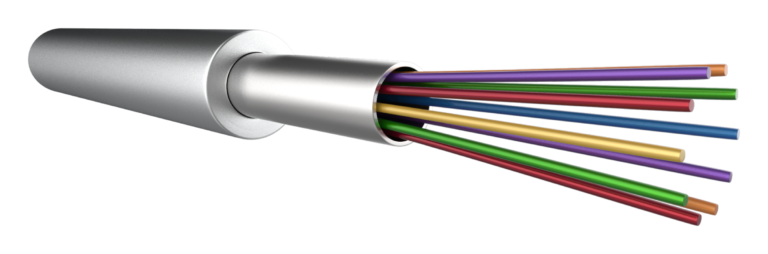

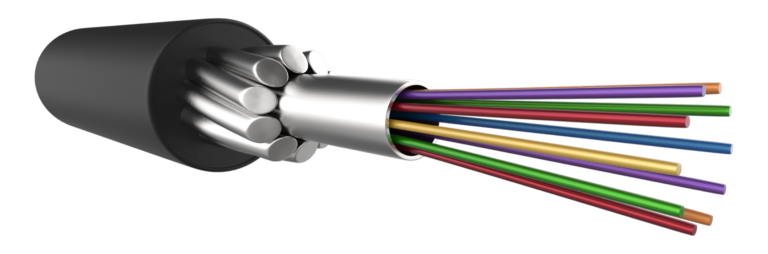

Structural Health Monitoring (SHM) based on fiber optic solutions is relatively new. It is based on an interdisciplinary branch of engineering that provides accurate and real-time insight to the critical elements of the infrastructure objects such as a bridge, tunnel, railway et cetera. The primary function of structural health monitoring is to ensure the safety and to plan, predict and optimize maintenance activities. The result of this monitoring and building database models on the gathered data is that the knowledge of the behavior of the infrastructural objects will increase. In this sheet we will describe the possibilities of SHM of our tunnel application. Quantifying tunnel performance requires a distributed network of sensors. Recent development in fiber optic sensing (FOS) technologies enables the possibility for global structural monitoring using Fiber Bragg Grating (FBG) sensors. These sensors combined with appropriate topologies and networks can provide the necessary information for assessment of a wide range of parameters that are relevant for the structural behavior.

FBG

Fiber Bragg Grating

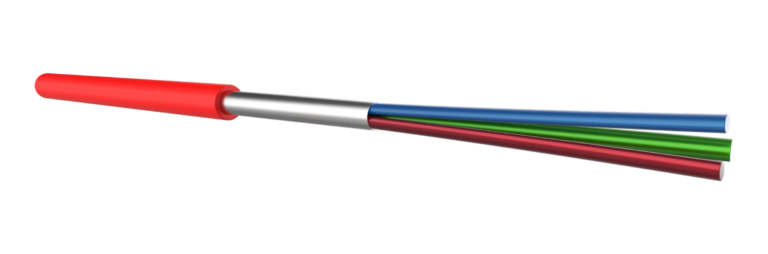

The FBG technology has great characteristics for both the multiplexing capability as well as self-referencing. Several sensors, with different functions, can be connected in series on a single fiber without signals being confused. The necessary cable length becomes considerably smaller because of this technology. The connection between the measurement unit and sensors are ensured via standard telecommunication fibers. A distance of several tens of kilometers can be reached. Therefore you can cover a large area to measure without the need of additional equipment and a power connection on all measurement locations. For each grating a reflected wavelength, which is an absolute parameter, is defined. This means there is the possibility of turning off or changing the measurement unit without the need to perform a static calibration or determining a new zero value. Looking at the explanation above, we can easily say that by implementing our Structural Health Monitoring solution the safety of the tunnel will improve and because of the collected data the predictability of maintenance can be reached. This represents both a public as well as a economic goal.

Functions

- Displacement

- Integrity

- Cracking

- Convergences

- Strain

- Settlement

- Separation of layers

- Movement

- Vibration

- Temperature

Advantages

- Long life time: Maintenance-free operation

- Real-time monitoring

- High sensitivity (Micrometer)

- No interferences from external ressources, operation in harsh environments, as the technology is immune to EMI/RFI

- Up to tens of sensors in one per channel

- No power supply needed at the sensor site – passive sensors

- Sensing network of discrete sensing points

- Large distance between the tunnel and evaluation unit (tens km)

- Different parameters (strain, temperature etc.) in one series/per channel

- Permanent monitoring – 24/7

- Remote access

Your Profits

- Service and maintenance planning

- On-line and real-time information about the structure

- Early warning in case of events

- Prevention of catastrophic failures

- Use of existing fiber-optic networks

- Managing remote areas with a single system

- Reporting and data analysis in accordance with SLA

- Customized solutions and adjustments easy to implement

- System management and data acquisition via internet

- System autonomy and immediate action via relays, email, LED