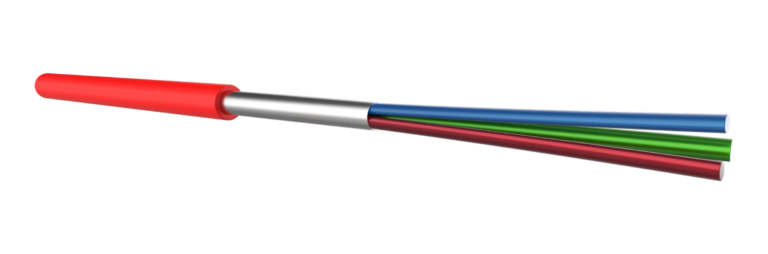

FIBER IN METAL TUBES

Trisens Cable

- Data transmitting fiber optic sensing cable

- Ultra-thin optical sensor

- Acoustic (DAS), Strain (DSS), and Temperature (DTS) Sensing

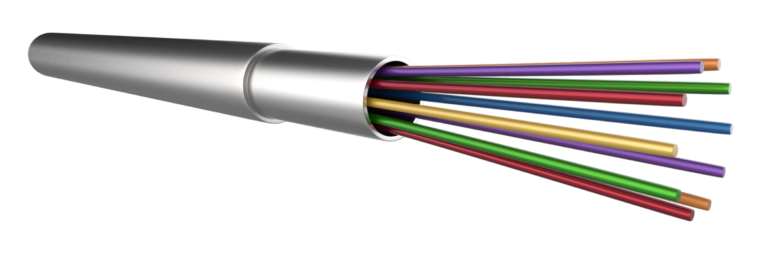

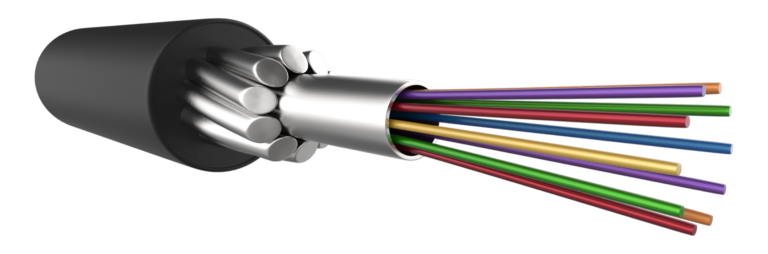

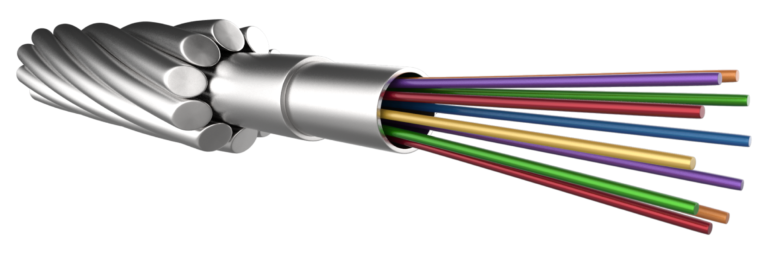

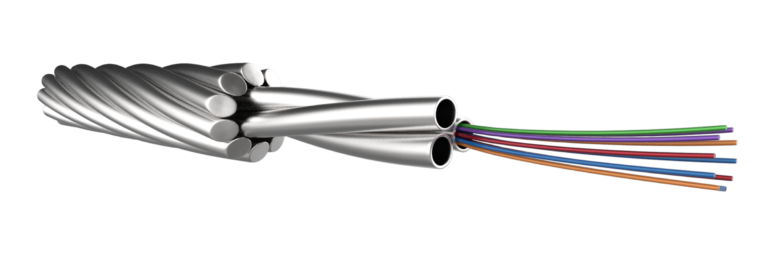

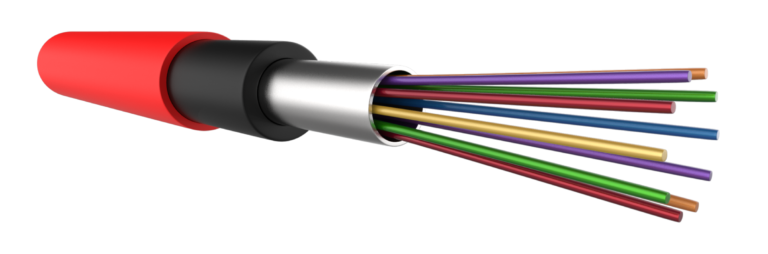

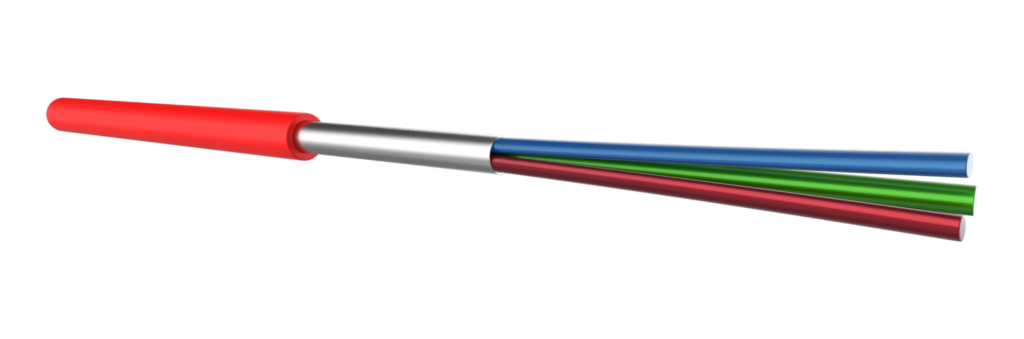

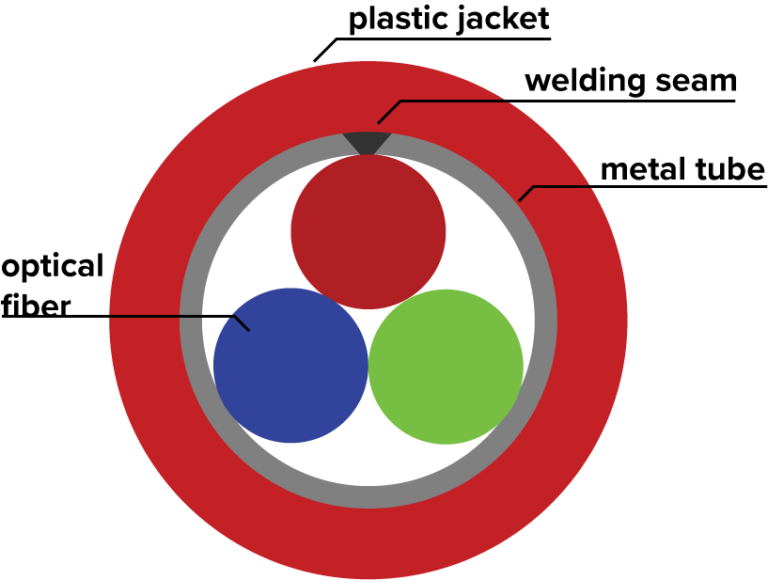

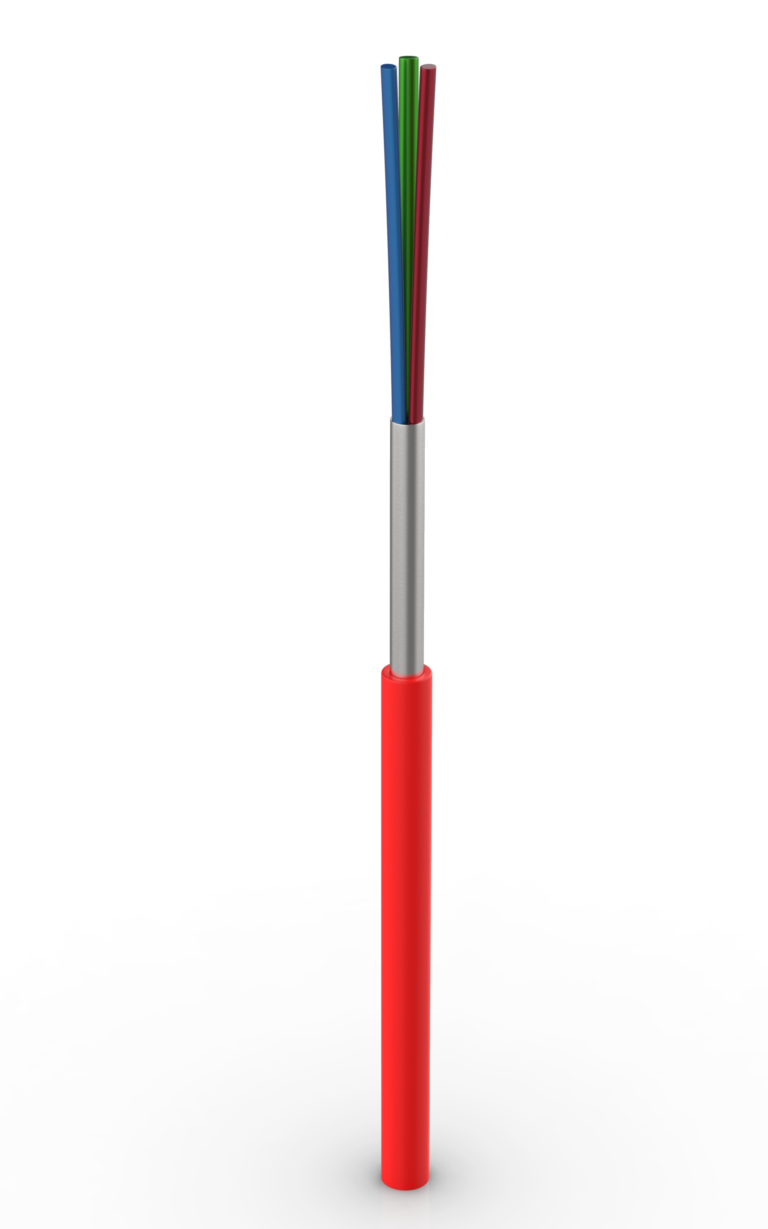

Trisens is our ultra-thin signature optical sensor. With an outer diameter of just 3 mm, Trisens is optimized for Distributed Acoustic Sensing (DAS), Distributed Strain Sensing (DSS), and Distributed Temperature Sensing (DTS). It also performs tremendously well when faced with other sensing applications and data transmission. In addition, the outer polymer sheath and high-grade steel tube give the cable enhanced flexibility and high resistance to mechanical stress.

The cable weighs only 11 kg/km, incredibly light for a high-performing optical sensor cable. As a result, it’s an excellent sensing solution for direct installation and comes ready for deployment. Additionally, its uniquely thin diameter and low weight make it a preferred option for integration in larger optical fiber configurations.

If you’re looking for an optical sensor and you think our Trisens fiber optic sensing cable is suitable for your project, get in touch to speak to one of our experts today. We approach every project as a unique challenge and deliver a custom solution to guarantee the greatest chance of success.

-

Three fibers

-

Sensing ready

-

Direct installation

Specifications

| Product abbreviation | TTC |

| Cable usage | Sensing |

| Outer diameter | 3 mm |

| Approx. Cable weight | 11 kg per km |

| Tube material | High anti-corrosive |

| Jacket Material | Polyamide - RED |

| Operational temperature range | +/- 15°C range on request |

| Type of fibers | G.657 A1 |

| Perfect usage for | Different sensing jobs |

| Central Brillouin Frequency | 10.6 GHz – 10.8 GHz |

| Strain sensitivity dfB/dɛ | 490 MHz/% |

| Temperature sensitivity dfB/dT | 1.1 MHz/°C |

| Maximum continuous length | Up to 10 km |

All values, product specifications and other given data are subject to change without notice to improve reliability, function, design or otherwise. Information contained in this data sheet are up-to-date as at the date of issue. As NBG cannot control or anticipate the conditions under which this product may be used, each user should review the information in specific context of the planned use. To the maximum extent permitted by law, NBG will not be responsible for damages of any nature resulting from the use or reliance upon the information contained in this data sheet.

Product overview created by Patrick Weissinger – 21.03.2019

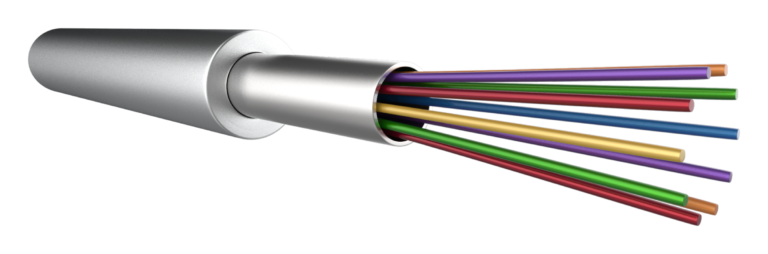

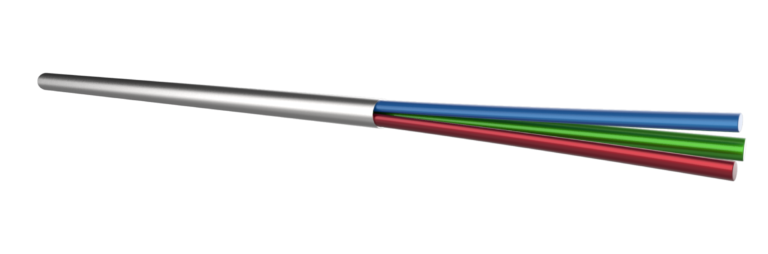

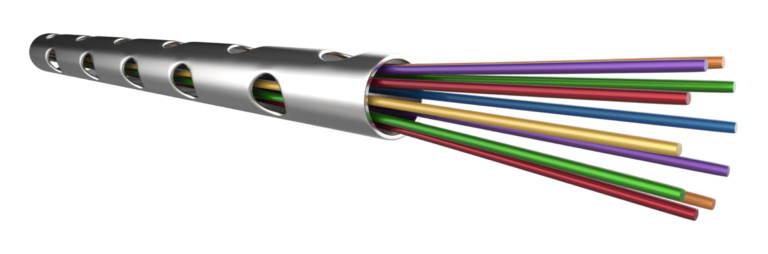

Optical fiber

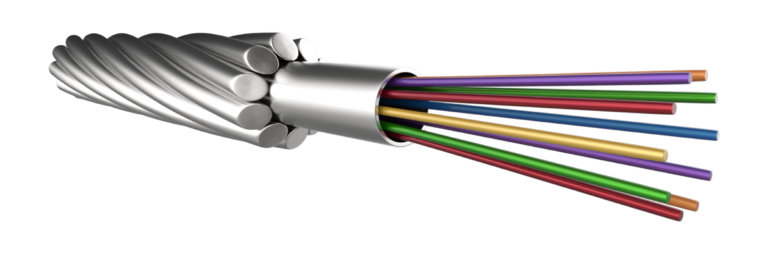

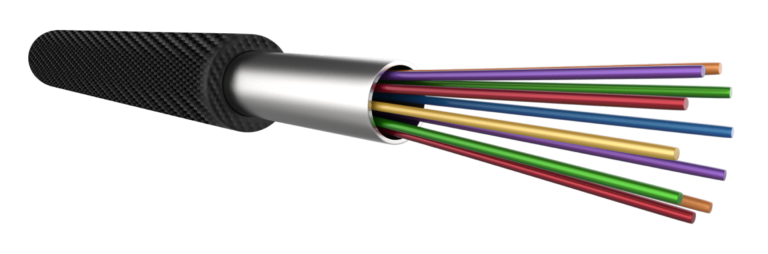

Metal tube

Plastic sheath

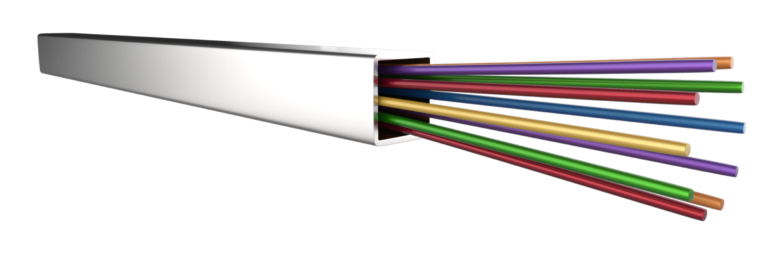

Applications