FIBER OPTIC SENSING

BRIDGE MONITORING

Monitoring Made Easy

We at NBG develop cutting edge technology for contemporary monitoring systems. With our analyse tools you can monitor structures from anywhere in the world. On this page you can read more about our advanced systems.

What can be monitored?

- Static load

- Dynamic load

- Strain

- Bending

- Cracks

Technology

SHM

Structural Health Monitoring

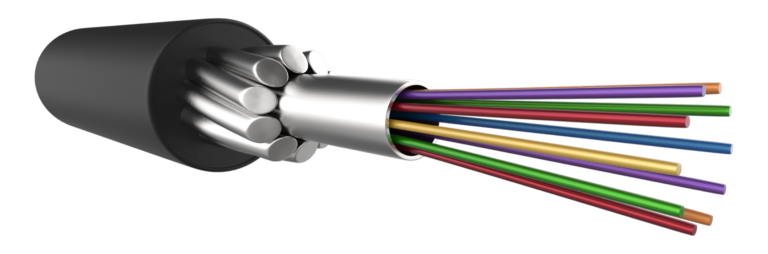

Monitoring the structural integrity of civil infrastructures is called Structural Health Monitoring (SHM) and is nowadays more and more important issue to reduce the cost of ownership. The primary function of monitoring is to ensure the safety of the structure, as well as to optimize its maintenance. Our SHM monitoring system is based on Fiber Bragg Grating (FBG) technology and brings many advantages over the conventional sensing methods, making health monitoring of large structures easier.

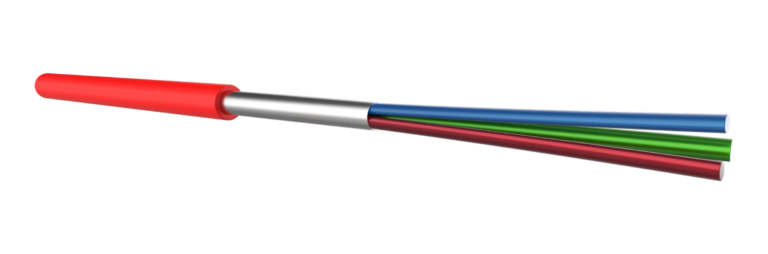

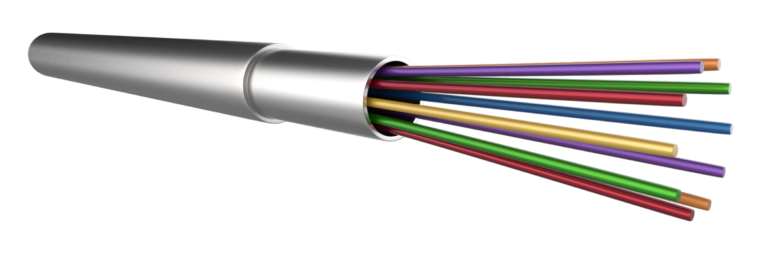

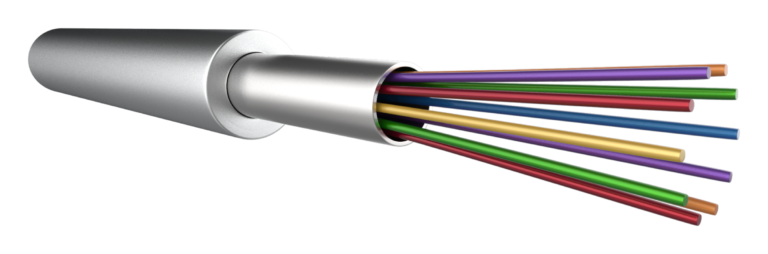

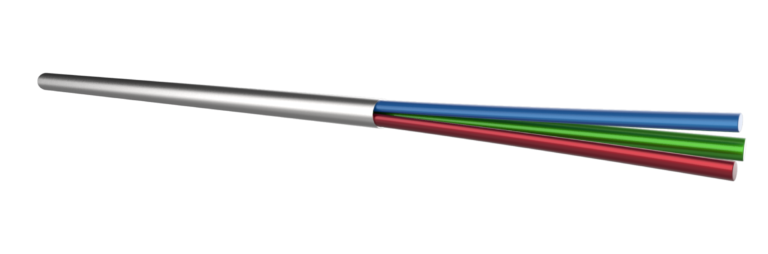

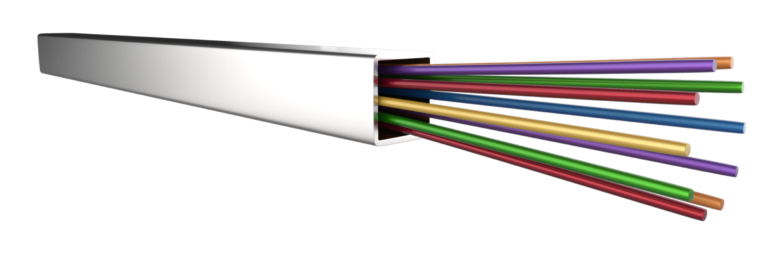

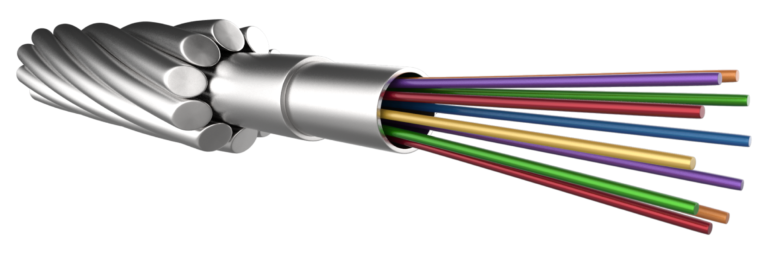

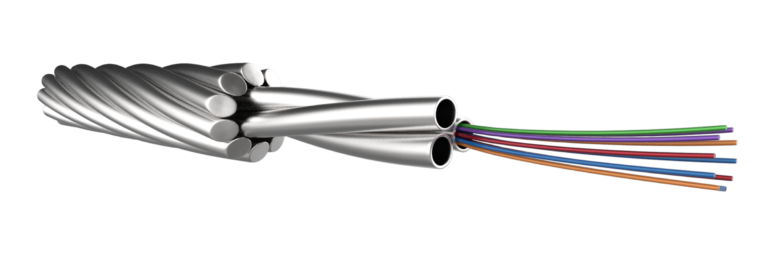

FBG – Fiber Bragg Grating

The FBG has great characteristics of their multiplexing capability and self-referencing. This means that several sensors, with different functions, can be connected in series on a single fiber without signals being confused and with necessary cable length becoming considerably smaller. The connection between unit and sensors is ensured via standard telecommunication fibers. A distance between unit and sensors can be up to several tens of kilometers. Therefore you can cover a large area with one unit and lots of sensors.

Being the measurement for each grating a reflected wavelength, which is an absolute parameter, there is the possibility of turning off or changing the measurement unit without the need to calibrate or determine a new zero.

What can be monitored?

- Static loading

- Dynamic loading

- Bending

- Cracking

- Displacement

- Settlement/Movement

- Strain

- Deflection

- Vibration

- Speed of passage

- Temperature

- Wear

Advantages

- High sensitivity

- No power supply needed at the sensor site – passive sensors

- Sensing network of discrete sensing points

- Large distance between the bridge and evaluation unit (tens km)

- Operation in harsh environments, as the technology is immune to EMI/RFI

- Long life time, maintenance-free operation

- Real-time monitoring

- Up to tens of sensors in one series/per channel

- Different parameters ( strain, temperature etc. ) in one series/per channel

- Several sensors (different parameters) in one series/per channel

- Permanent monitoring – 24/7

- Remote access

Your Profits

- Early warning in case of events

- Prevention of catastrophic failures

- Service and maintenance planning

- Managing remote areas with a single system

- Use of existing fi ber-optic networks

- System autonomy and immediate action via relays

- On-line information about the structure with fast response

- Reporting and data analysis in accordance with SLA

- Possibility of customized solutions and adjustments

- System management and data aquisition via web