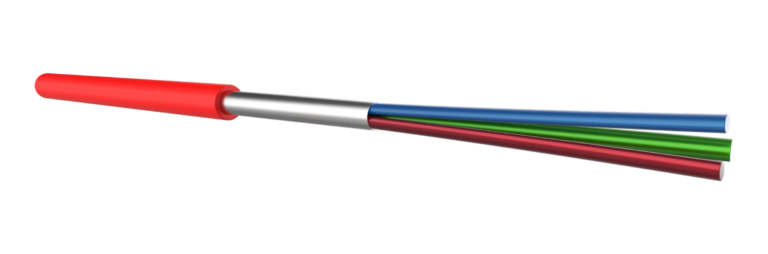

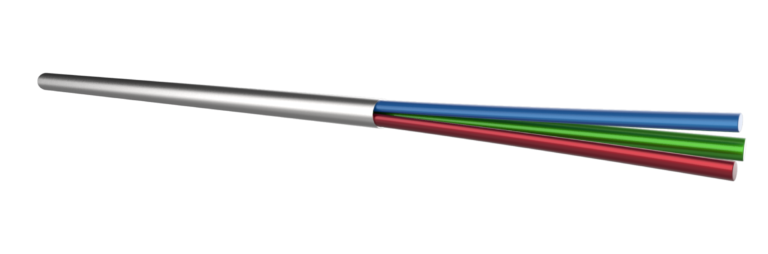

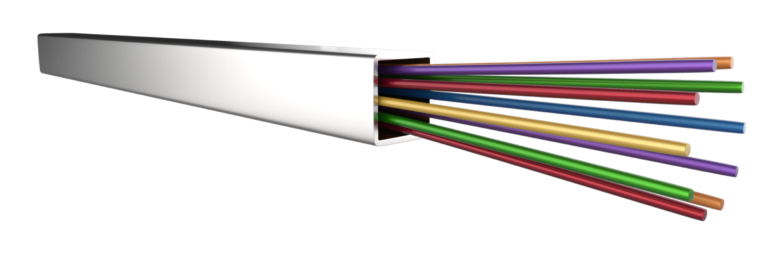

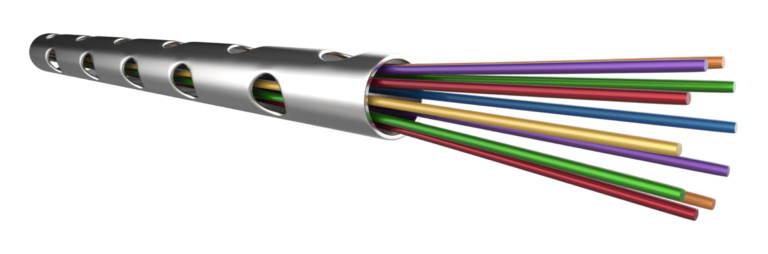

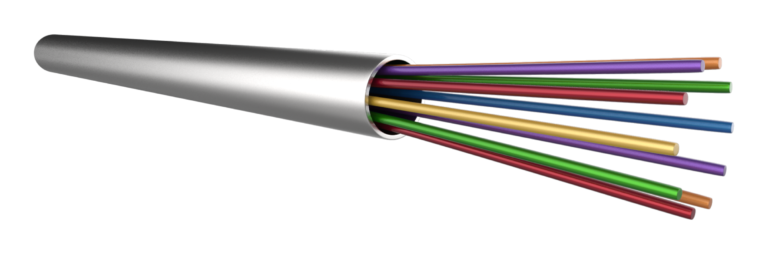

FIBER IN METAL TUBES

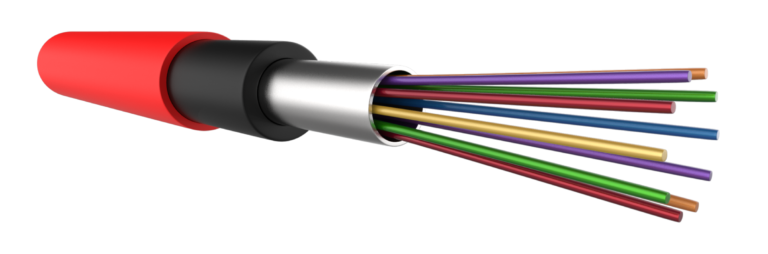

Self-Supporting Downhole Cable

- High tensile strength for harsh surroundings

- Vertical installation for the Oil & Gas Industry

- Suitable for tools

A Downhole Cable for Harsh Environments

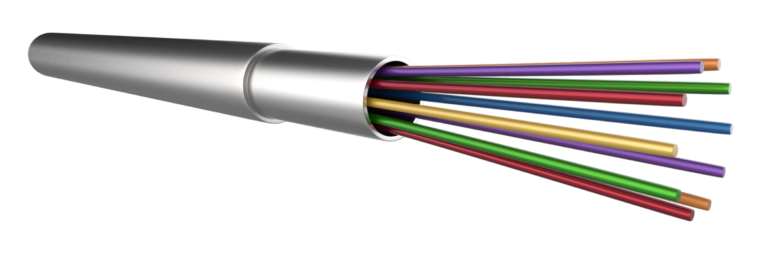

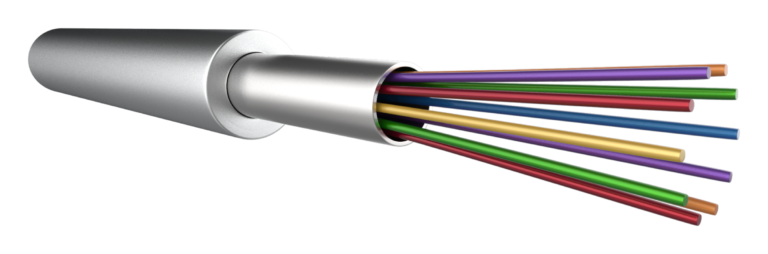

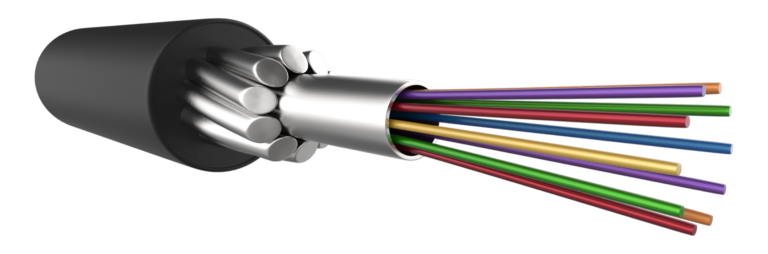

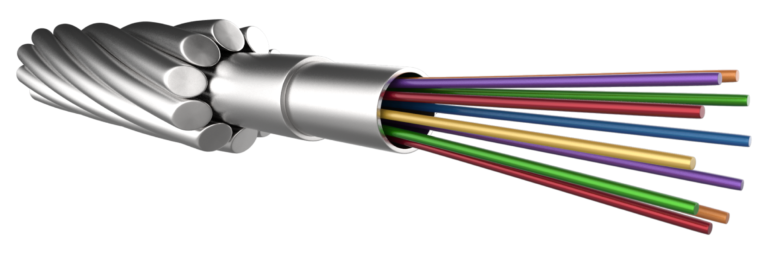

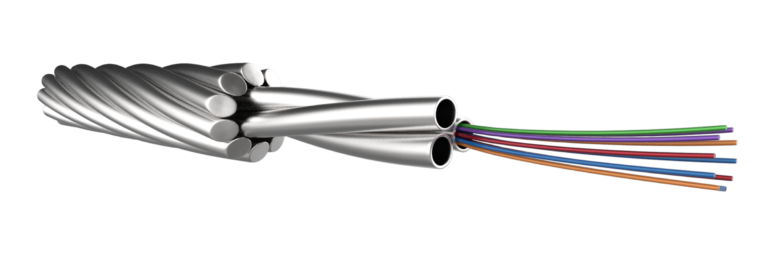

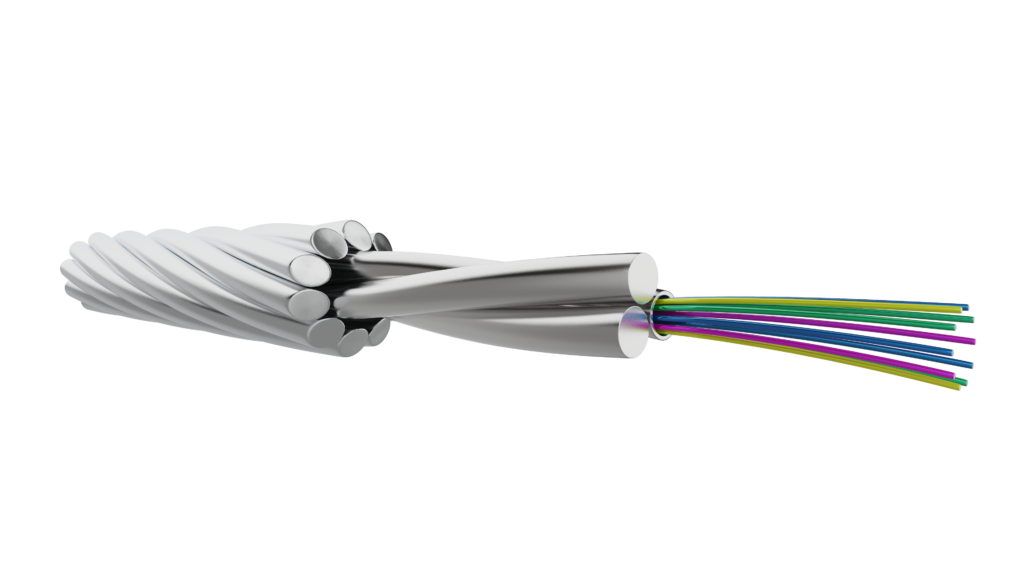

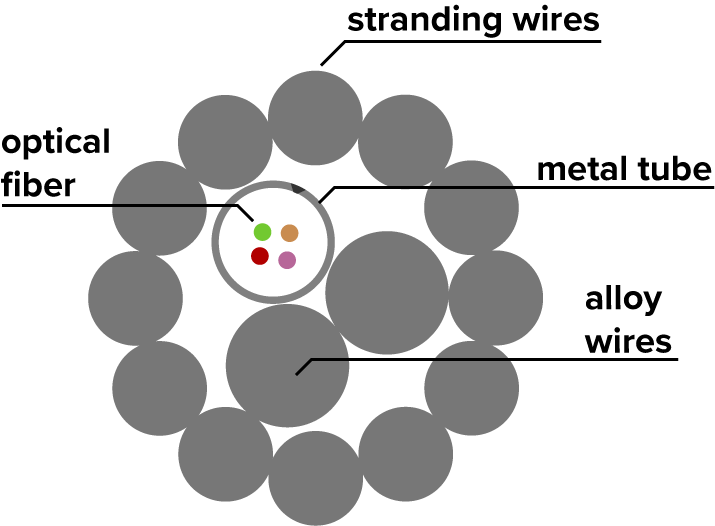

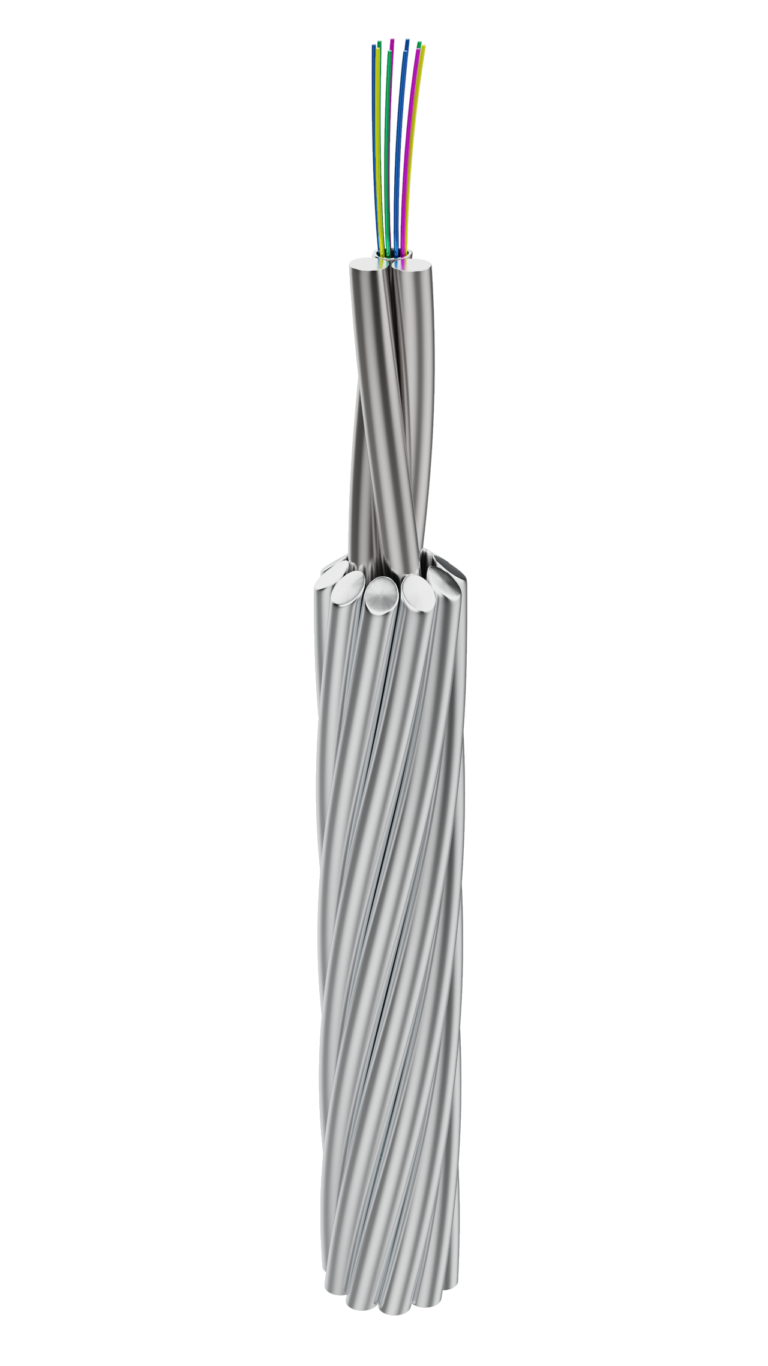

The intelligent design of the Self-Supporting Downhole Cable (SDC) is the standout characteristic of this fiber optic cable. The helical shape of the FIMT (Fiber in Metal Tube) locks the EFL in place; this is true even for long vertical installation lengths, where fibers in straight cables usually fall because of gravity.

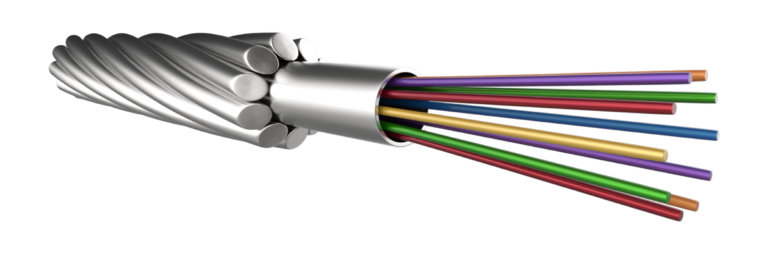

The outer stranding wires are made of highly corrosion-resistant steel grades, guaranteeing the fiber optic cable’s performance and flexibility even in the harshest environments. In addition, the design allows for a separation between the optical fiber and potential copper wiring, making it perfect for integration in hybrid cables.

The downhole cable is designed for the harsh surroundings of the Oil & Gas Industry, providing expert Distributed Temperature Sensing (DTS) and Distributed Acoustic Sensing (DAS). Contact one of our experts today if the Self-supporting Downhole Cable is the product you need for one of your projects. Every one of our cables is customizable to the precise requirements of every challenge.

-

Anti corrosive

-

High crush resistance

-

Designed for downhole

Specifications

| Product abbreviation | SDC |

| Cable usage | Data Transm. & Sensing |

| Total outer diameter | 8.50 mm |

| Approx. Cable weight | 317 kg per km |

| Excess Fiber Length (EFL) | Exceeds 0.6 % |

| Operational temperature range | -60°C up to +800°C |

| Maximum continuous length | Up to 15 km |

| Ultra-High tensile strength | > 42 kN |

| Ultra-High crush resistance | Tests acc. latest standards |

| Cable material | High anti-corrosive mat. |

| High corrosive resistance | Made of Alloy material |

| Perfect usage for | Vertical installation |

All values, product specifications and other given data are subject to change without notice to improve reliability, function, design or otherwise. Information contained in this data sheet are up-to-date as at the date of issue. As NBG cannot control or anticipate the conditions under which this product may be used, each user should review the information in specific context of the planned use. To the maximum extent permitted by law, NBG will not be responsible for damages of any nature resulting from the use or reliance upon the information contained in this data sheet.

Product overview created by Patrick Weissinger – 21.03.2019

Optical fibers

Metal tube and alloy wires

Stranding wires

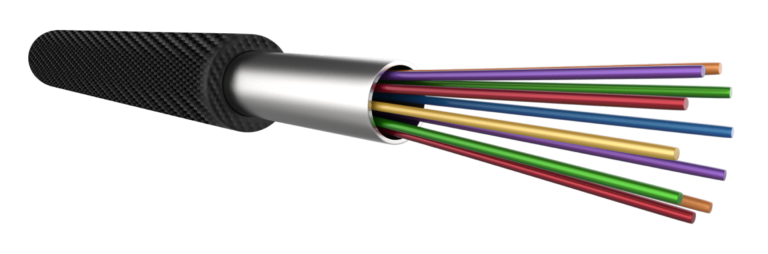

Applications